IMC has been successful in saving two important handicrafts from extinction, namely; Talli and Mansag at the village of Shandaweil, Soohag Governorate, and pottery industry at Al-Kharga Oasis, New Valley Governorate.

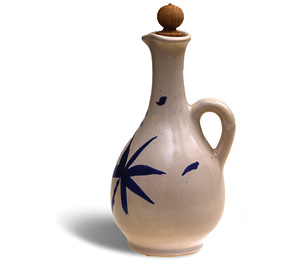

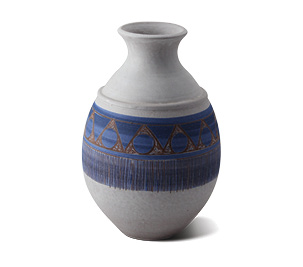

Pottery in Al-Kharga Oasis – Al Wadi Al-Gedid

Al Kharga Oasis in New Valley is one of the most promising oases, as it teems with dates factories, an onion drying plant, and handicrafts such as making palm branches “Argoon” , basketry, and pottery.

In 2006, IMC visited the Pottery Industry Center in Kharga Oasis, , due to the importance of pottery industry in Egypt. It is worth-noting that New Valley pottery is made of a one of a kind clay, where mountains of this clay are exclusively found in this Governorate. It is considered one of the distinctive and unique colors in pottery and has a high consumer appeal.

IMC study revealed that this cluster’s sales do not exceed 10,000 pounds annually, due to many problems facing it in the manufacturing processes, starting from mixing and preparation of the clay for formation as well as the method of burning, leading to a low-quality product at a very low price. This has led to the turnover of many artisans, as the number of workers decreased from 33 workers to 10 workers (6 women, 4 men) due to the lack of fixed income or stability of work.

IMC intervened in a number of ways to solve those problems, starting with the clay preparation and formation, and different burning methods, resulting in high quality products at a reasonable price. Therefore, IMC helped the Cluster to participate in Furnex 2007 where it made LE 7700 of sales in just five days, compared to a LE10.000 over a year! Here came the real strating point: the Cluster resumed operations, and retained labor, added new labor to raise the number of workers from 10 to 36 (14 male – 22 female), in addition to 6 fine artists.

New products and new technologies were introduced in the manufacturing process; such as the use of glazes in finishing and the production of new designs, such as making large volumes and lighting units. This led to sustainability, and more job opportunities.

Talli and Mansag at the village of Shandaweil, Soohag Governorate

Gezeret El-Shandaweil village, one of Upper Egypt villages, located 8 km North of Sohag, is a poor village in which women work in the embroidery craft with Talli threads on fabrics as a source of income for assistance in raising children. Women depends in marketing their products on exhibitions organized by the Social Fund for Development (now, Micro, Small, and Medieum Enterprise Development Agency MSMEDA), the governorate, and the productive families.

IMC visited the village and discussed means of development to be provided. It was noticed that there is another craft called Al-Mansag craft that is produced only by five elderly women in the village, meaning that the craft is extinctionable, despite the high demand on it in the local and international markets.

An action plan has been developed as follows:

- Forming groups of girls and using the five elderly women to train the girls of the village, aiming to establish a new generation and revive the craft. Indeed, the number of women and girls working in Al-Mansag craft has now reached 150 women and girls with a high degree of competency and mastery.

- Specialists to train 25 girls and women to create new designs for existing Mansag themes, provided that these themes are inspired from the rural environment.

- Specialists to train 25 girls on how to coordinate colors of threads used and combine them to come up with a product of a great art and beauty.

In parallel, the Talli craft was also considered, as IMC noticed that the existing Talli products are entirely similar with no element of innovation and creativity, representing a marketing challenge. Hence, an action plan has been prepared as follows:

- Increase the number of workers by training 50 girls and women as new workers on embroidery with Tali threads on tulle fabrics.

- Get rid of sterotype production and search for an element of development. Twenty five girls were trained on embroidery with Talli threads on various cotton and hand-woven fabrics such as Ferka (scarfs) of Naqada and, resulting in a link among many handmade products together to create new marketing opportunities, and therefore, Sales increase.

Twenty five girls were trained on new products made from Talli (Curtains, cushions, sheets …etc), targeting a new client category.

Additionally, and to close the production circle within the Cluster, 25 girls and women were trained on sewing and tailoring.

The, IMC contracted foreign designers to help the Cluster initiate new products in line with external markets.

IMC had a prominent role in solving the Cluster’s marketing problem by displaying products at the Creative Egypt showroom, as well as in major local fairs such as Furnex, which had witnessed good deals with shop owners and bazaars. This is in addition to participation in international exhibitions in various countries such as Germany, France, America, the Emirates and Kurdistan, which had a real impact on increasing production.

Then comes the problem of the Talli key raw material, which is imported from India. Prices of threads are controlled and supplied by a number of traders, which threatens the continuation of the craft.

Therefore, IMC had a prominent role to play in trying to solve this problem. It searched for other manufacturers and suppliers, especially in countries known for their interest in handicrafts. Therefore, IMC was able to avail a number of manufacturers of high-quality and affordable Talli threads in India, and it provided technical support and assistance to the association representing the Cluster’s members.